Laser-Cut Technology

Radial Cut vs. Straight Cut – What A Painless Decision!

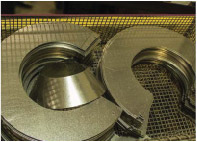

Snappy's latest innovation, Laser-Cut Safety Fittings™, NEW to the HVAC industry. It’s cutting edge technology that virtually eliminates safety problems stemming from sharp corners and ragged edges.

Snappy's latest innovation, Laser-Cut Safety Fittings™, NEW to the HVAC industry. It’s cutting edge technology that virtually eliminates safety problems stemming from sharp corners and ragged edges.

Using fiber optic lasers, Snappy is able to produce parts that far and away obsolete conventional manufacturing. Our precision is unmatchable and edges are smooth cut for tight, safe, consistent fitting during installation.

Snappy’s Comfort Distribution Products™ have been evolving over nearly six decades of manufacturing to the highest proven standards of safety, efficiency and reliability. Our latest Safety Fittings provide further proof of our commitment to you, our distributors, and the contractors you serve.

Snappy Introduces Laser-Cut Safety Fittings™ To Full Line Of Comfort Distribution Products™

Contractors now have a new line of easier and faster to install HVAC components designed and manufactured to provide greater system integrity for the project while also providing enhanced safety for installers.

Laser-Cutting Technology Delivers The Following Features and Benefits Versus Old Cutting Methodology.

- Compatible use on broad range of metals include both galvanized and stainless steel as well as aluminum, copper and brass.

- Order accuracy is enhanced as finished goods scheduling reports convert to cutting lists via advanced nesting/ cutting software.

- Software edits patterns applying a small radius (0.030”) to all 90° edges/corners virtually eliminating cutting hazards.

- The laser replicates the cut profile for standard and custom designs.

- Use of software and laser cutting technology maximizes raw materials and reduces waste sheet metal by 25 percent.